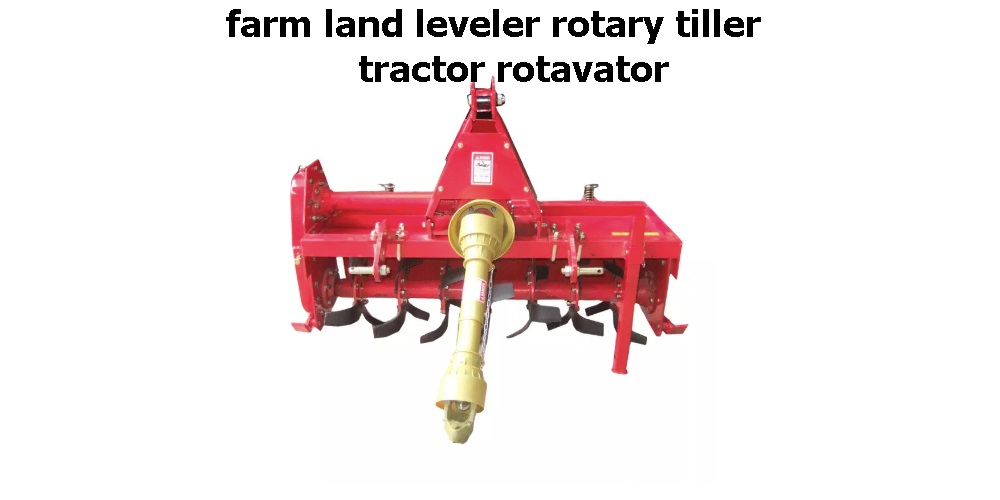

The type of power source that drives the rotavator determines whether it is known as a tractor-drawn or engine-operated rotavator. The blades and tines fastened to the shaft and powered by an external source are used to cut through the rubbish and soil.

The blades are the most important part of a rotavator since they are the part of the machine that actually drives it to prepare the seedbed and mix the leftover soil. Since these blades are designed to destroy weeds and operate at their highest level of effectiveness, they typically have the form of an inverted L.

The rotavator’s settings are modified to accommodate a variety of farming applications. Both the position of the back cover and the amount of pulverization of the soil can be adjusted to the user’s specifications. Adjustments can also be made to the depth skids to change the distance between the blade and the soil.

Various Forms of Rotavator

The rotavator is a flexible piece of machinery used in primary and secondary tillage, making it appropriate for various soil types. This article will go over a few different kinds of rotavators:

A Light Duty

The mini-series and hobby-series rota included in the assortment of light-duty rotavators are ideal for preparing the soil of small gardens, garden boundaries, small vegetable gardens, or allotments.

- This mini rotavator is ideal for maintaining and preparing small gardens because of its lightweight and compact design.

- It can aerate and loosen the soil to a depth of between four and five inches.

- It is the best machinery for weed control and pulverizing the soil.

Medium Duty

The medium-duty rototillers, including the standard series rotary tillers, are perfect for allotment gardens, greenhouses, nurseries, vineyards, and other types of gardens to aerate the soil, manage weeds, and promote water absorption around plants.

- Even the most demanding working conditions do not hinder the performance of the medium series rotavator.

- The formerly uncultivated terrain that has been compacted can now be prepared for planting.

- It can break up and aerate the soil to a depth of six inches.

- The medium-duty machine can work near plants and crops without causing any harm to them.

Because these rotary tillers of medium-duty are so simple to operate, you will be able to significantly cut down on the amount of labor you have to perform in the field.

Heavy Duty

Heavy lifting when it comes to cultivating huge amounts of land, rotavators are the most effective tools for farmers to use.

- Ensures a precisely aligned and finished seedbed with good performance in all working situations

- Rotor speed can be readily regulated

Maintenance of a Rotavator

Because a rotavator is a very precise and detailed piece of machinery, it needs to be properly cared for and maintained to have a long and healthy life.

Because of its job of digging up the soil, a rotary tiller’s engine oil and filter need to have their filter and oils changed regularly. This should be done at least once a year, after fifty hours of use, or whenever the oil looks dirty to the naked eye, whichever comes first. To keep the best performance, the air filter must be cleaned regularly, and the other parts must be washed after each use.

Maintenance and regular inspection of the agricultural machinery would not only ensure that the economic benefits of the machinery would continue to accrue, but it would also ensure that the safety of all those involved in its operation would not be jeopardized.