The selection of materials in press brake operations plays a significant role in determining the bending process’s quality, efficiency, and effectiveness. SMBC Tools offers insights into material considerations by emphasizing suitable materials for bending, thickness tolerances, and specialized tooling requirements.

This article discusses these essential aspects and provides manufacturers and individuals with valuable guidance for optimizing press brake operations.

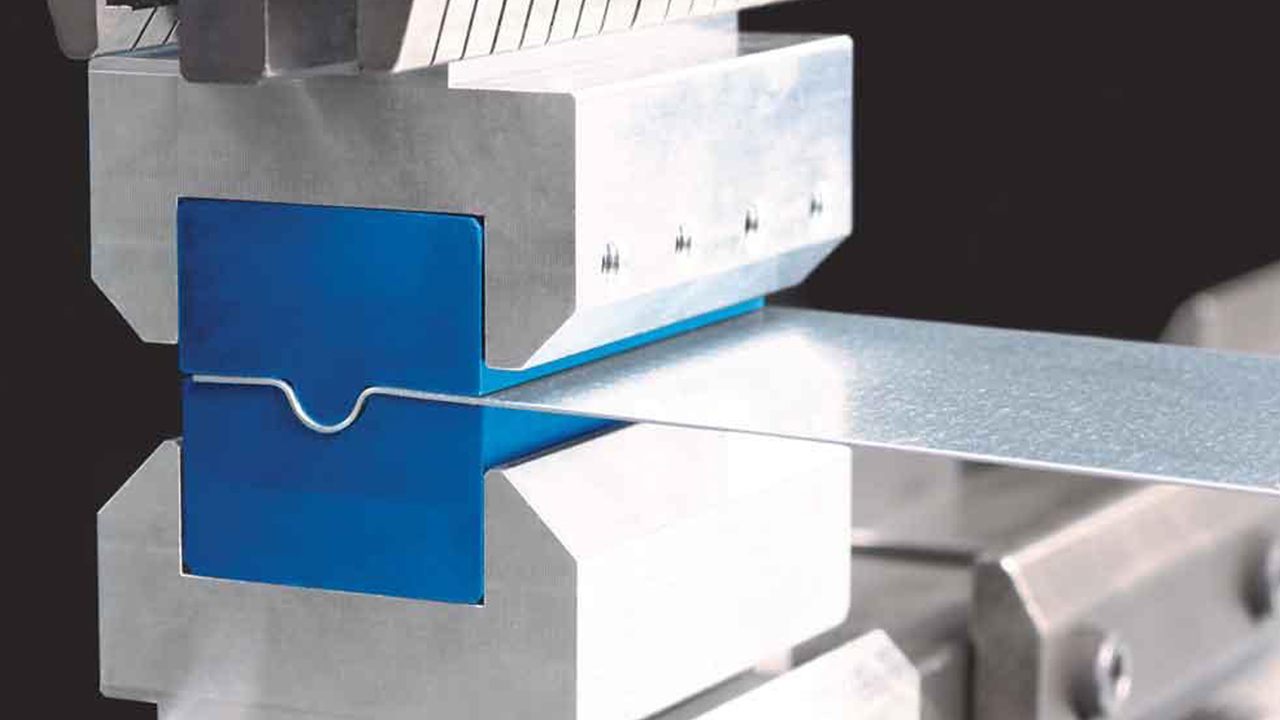

Suitable Materials for Bending

Choosing the appropriate material for your press brake project is the first step toward achieving the desired outcomes in press brake operations. Here’s a quick guide to suitable materials for bending:

Mild Steel

The workhorse of metal fabrication, mild steel, offers excellent bendability and formability. This makes it ideal for various applications. SMBC Tools provides a comprehensive range of standard and specialty tooling specifically designed for mild steel bending. This ensures predictable results and extended tool life.

Stainless Steel

Stainless steel requires careful consideration due to its higher springback tendencies because it’s renowned for its corrosion resistance and aesthetic appeal. SMBC’s advanced tooling solutions incorporate specialized coatings and geometries that cater to the specific needs of stainless steel bending, minimize springback, and ensure precise results.

Aluminum

The softer nature of lightweight and versatile aluminum necessitates tools with reduced cutting edges and precise geometries to avoid surface marring or cracking. SMBC’s aluminum-specific tooling addresses these concerns, guaranteeing clean bends and optimal performance.

High-Strength Steels

When strength reigns supreme, high-strength steels come into play. These materials demand robust tooling and precise control to achieve desired bends without compromising structural integrity. SMBC’s premium tool steels and innovative designs tackle the challenge of high-strength steel. Consequently, they deliver reliable performance and consistent quality.

Material Thickness and Tolerance

Material thickness significantly impacts the bending process. This necessitates meticulous attention to detail and precision. SMBC Tools caters to a wide range of thicknesses and ensures you have the perfect tool for the job.

Accurate measurements and adherence to specified tolerances ensure consistent bending results, dimensional accuracy, and compliance with industry standards. Remember, thicker materials require proportionally higher tonnage and tool strength, while thinner sheets necessitate careful control to avoid distortion.

Choosing the suitable thickness capacity for your press brake and utilizing SMBC’s tooling options guarantee optimal bend quality and minimize the risk of material damage.

Specialization is Key

Not all materials bend the same way. Some, like copper or brass, require specific tooling considerations due to their flexibility or susceptibility to marking. Tailored solutions, such as those offered by SMBC Tools, address particular material requirements, bending complexities, and operational challenges.

They have customized tooling configurations, advanced coatings, and specialized designs for different materials. This ensures compatibility, efficiency, and precision in bending applications. You can enhance flexibility and performance by leveraging those specialized tooling solutions.

Takeaway

Material considerations remain integral to SMBC’s press brake operations. By prioritizing material selection, understanding thickness tolerances, and leveraging specialized tooling solutions, you can optimize efficiency, enhance quality, and achieve desired outcomes in press brake applications. Remember, choosing the right tools is the first thing to always consider for bending perfection.