Machines are replacing people in all fields. Companies are doing this as many tasks can be done better by machines instead by humans with great efficiency. An automatic case-making machine is used for the same purpose.

Automatic case-making machines are used to make casings of books, table calendars, cigarette boxes, electronic boxes, game boards, folders, etc. They are convenient to use and take much less effort than the traditional ways automatic case making machines are needed of the hour. It can increase the speed of the packaging processes and deliver precise work, which makes them the owner’s first choice.

Types of Automatic Case-Making Machines

Automatic Case-Making Machine has different types and customers can select them according to their needs.

Multifunctional case-making machine

It is used to make bookcases along with cardboard cases. It can perform multi-tasking and can produce a single case for mass production at the same time. It can be a great option for business owners who want to make cases on a very large scale.

Semi-automatic case-making machine

This type of machine has a low budget and can be a good option for small business owners. It is semi-automatic so needs a human touch to make casings.

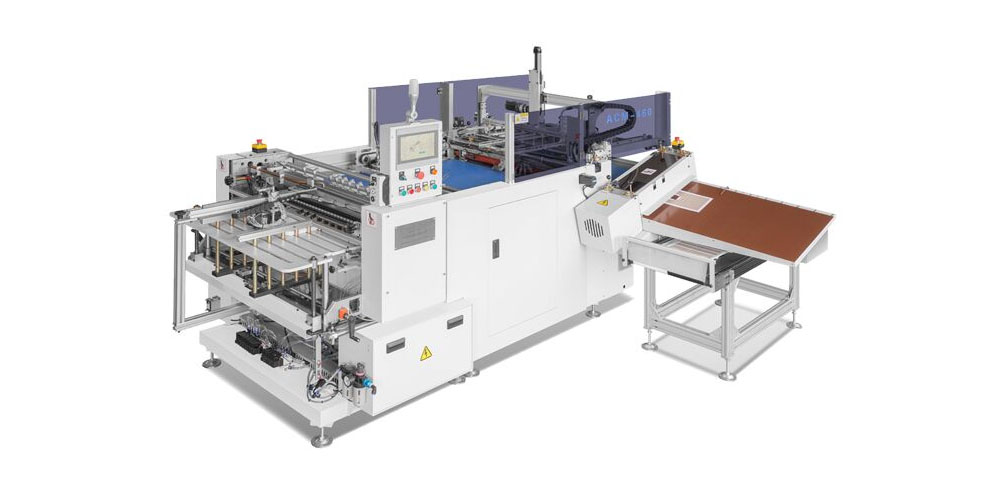

Fully automatic case-making machine

These machines are fully self-operated and don’t need any human being to operate. All you have to do is to make it set up and it’s ready to operate in a day or two. It is expensive but this expense can turn into a long-term investment. It will speed up production, take less time and reduce the cost as no labor is involved.

High-speed digital automatic case-making machine

In business, time keeps great importance. This high-speed digital machine can help owners to rise their businesses to a great level. It can help them to produce mass production in less time. It is automatic so no human is required and there is a lesser chance of errors and repetition.

Equipment Features

These machines offer many features in one product. Following are some of them

Glue system

It can automatically make layers of glue by making it thick and thin. It helps to improve the quality of the cases which they make. It is also time-saving.

Viscosity device

It can dilute the material by itself and maintains the viscosity of the material according to the requirements.

Cam

These machines have a cam system that improves the machine’s stability and makes it precise and easy to check.

Brush Device

This device helps to make material without scratches. It makes sure that the folding is tight.

Two board feeding

It helps to change the making from normal boxes to collapsible boxes easily and saves time.

Advantages

These machines can benefit a lot to their users. It can save time and money. These machines are a one-time expense then they will prove as a great investment. It helps to speed up the process with any tension or threat. It provides accurate results so quality is never compromised. It can be operated with a small skill set and is very convenient to use, as all functions are automatic.

Wrap Up

Customers can get a lot of benefits from these machines. You can select the machine according to your budget. It also allows the users to select it based on the features as if they want high speed.