Using computer-aided design (CAD) software, rapid prototyping creates a physical model of a design. It is used in various industries, including automotive, aerospace, medical, and consumer goods, to test and refine designs before they go into production. Rapid prototyping services have become increasingly popular, allowing businesses to create prototypes quickly and cost-effectively. In this article, you’ll learn about rapid prototyping and the advantages of using prototyping services. Many medical parts prototypes are made by this method. Let’s learn more about prototyping and services.

What is rapid prototyping?

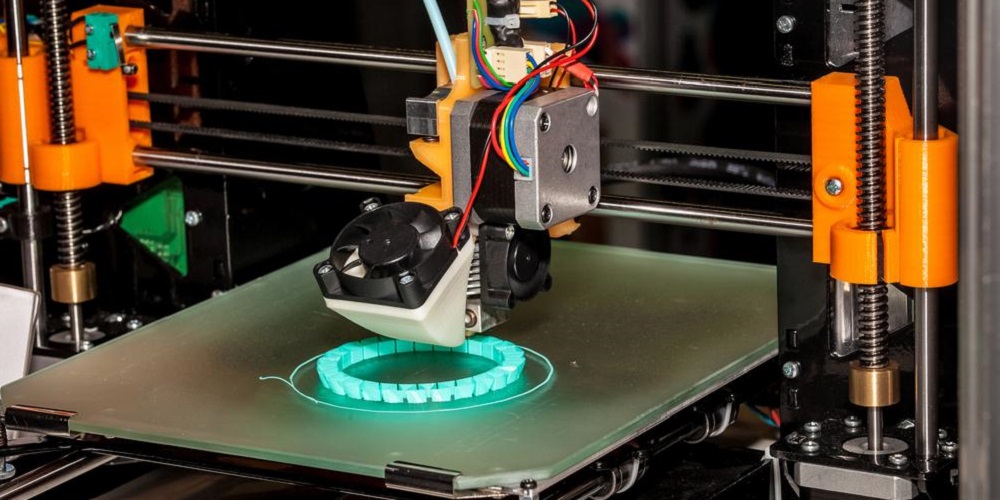

Rapid prototyping, also known as 3D printing or additive manufacturing, is a process that uses computer-controlled machines to build three-dimensional parts from a digital model. The process begins with the creation of a digital model using CAD software. This digital model is then sent to a 3D printer, which creates the physical prototype by building up successive layers of material. The result is a highly accurate and detailed physical model that can be tested and refined.

Advantages of rapid prototyping services

There are many advantages to using rapid prototyping services. Here are some of the key benefits:

Faster turnaround times

Rapid prototyping services are great because they make prototypes fast. Traditional manufacturing methods can take weeks or even months to create a prototype. With rapid prototyping, however, a prototype can be created in days or even hours. Businesses can quickly go from design to testing and refinement, saving time and money.

Cost-effective

Rapid prototyping is often more cost-effective than traditional manufacturing. Since it’s digital, there’s less waste and less resource consumption. Furthermore, prototyping can help businesses identify and address potential issues early in the design process before investing a lot of money in manufacturing.

Highly accurate

Our rapid prototyping services produce detailed, precise physical models. Testing and refining designs require this level of accuracy. Businesses can also create complex geometries and shapes that are hard or impossible to make with traditional manufacturing.

Customization

Rapid prototyping allows for a lot of customization. Digital processes make it easy to modify designs and make custom parts. Especially useful in industries like aerospace and medicine, where parts may need to be customized.

Types of rapid prototyping services

Rapid prototyping comes in several forms. Some of the most common are:

Stereolithography (SLA)

A UV laser cures a liquid resin in stereolithography, a type of rapid prototyping. A computer directs the laser to create the desired shape layer by layer.

Selective laser sintering (SLS)

Selective laser sintering is a rapid prototyping process that uses a laser to fuse powdered material. This process is particularly useful for creating complex geometries and shapes.

FDM (fused deposition modeling)

Thermoplastic material is used in fused deposition modelling to create the desired shape. The material is melted and extruded through a nozzle to build successive layers.

Conclusion

Rapid prototyping services offer many advantages to businesses across a variety of industries. From faster turnaround times to cost savings to high levels of accuracy and customization, rapid prototyping services are a valuable tool for testing and refining designs. With various options available, including stereolithography, selective laser sintering, and fused deposition modeling, businesses can choose the right prototyping service for their specific needs. If you’re in the design phase of a new product, consider working with a rapid level of accuracy.