Manufacturers use PVC-coated webbing because it provides exceptional durability, along with flexible strength, and shields against moisture. It serves multiple purposes in items like watch straps, belts, outdoor equipment, pet items, and more. This material works better than leather does while handling water exposure and heavy loads. Functional and design requirements for different products drive the need for product customization.

You can edit PVC webbing exactly how your project needs it to fit both visual and performance requirements. Since 2006, Sunmolin Plastic Technology Co., Ltd has led the industry transformation in TPU extrusion. Through extensive ten-year experience, Sunmolin helps product developers unlock enhanced strength and design capabilities in PVC webbing applications. Let’s dive right into this article to uncover the facts about how you can customize and what you can customize in pvc webbing.

Custom Dimensions: Width, Thickness, and Length

You need webbing with exact dimensions to work with every application. You can request custom webbing widths for belts or thinner material selection for watch straps. Sunmolin lets you make exact width, thickness, and length choices because standard sizes often do not match customer needs. Through their advanced coating process, the team produces webbing dimensions with exact precision. Sunmolin’s precise production creates a product that follows all your design details exactly. Accurate cutting ensures a neat finish and better compatibility with end-use items.

Punching and Cutting Customization

Customize the location and size of holes and openings to match your design plan. Through its operations, Sunmolin creates precise round holes or intricate patterns with smooth edges that enhance product quality. Punching with clean edges helps products stay together better during use and defends against edge wear to increase product lifetime.

Riveting for Functional Integration

Basic shapes need structural support to work correctly. Sunmolin uses riveting to build strong results. Sunmolin adds zinc-alloy rivets to webbing, which prevent rust formation without affecting the overall design. You achieve greater toughness and durability along with improved aesthetics and extended product usefulness. Outdoor accessories with functional parts like dual-purpose straps benefit from these customized additions. The metal fasteners maintain their position while boosting the product’s durability and visual appeal.

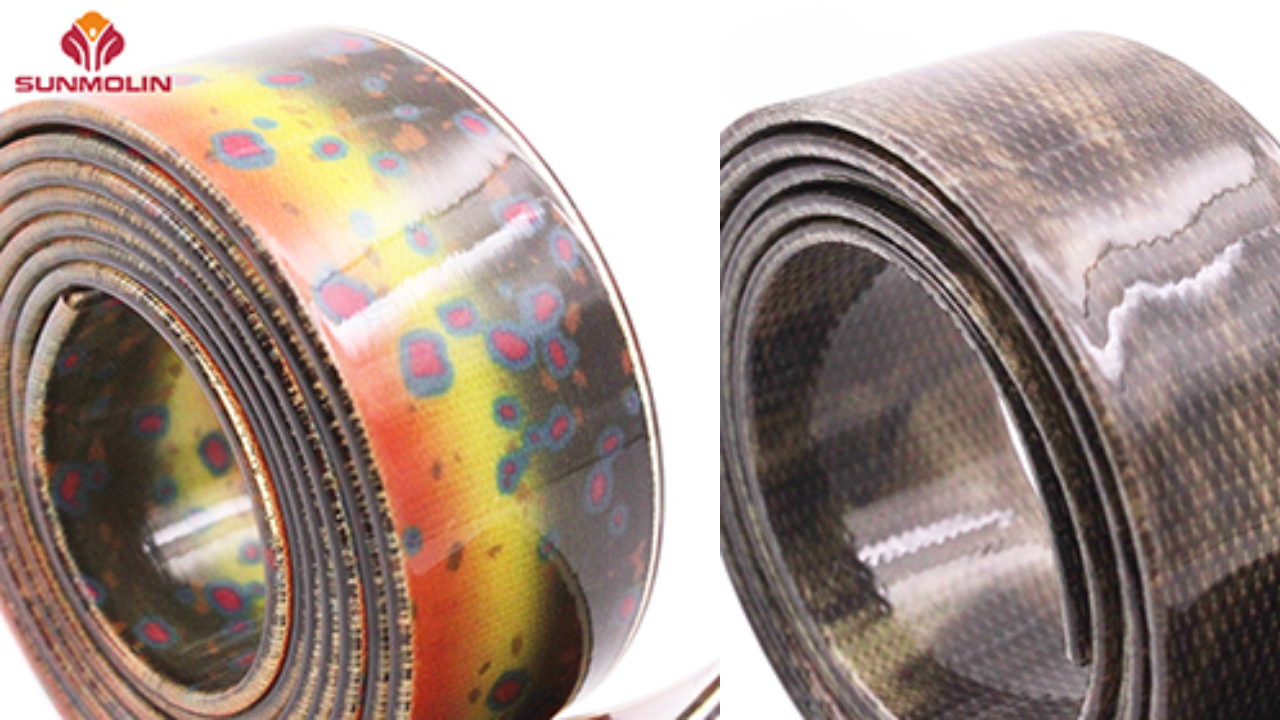

Custom Colors and Surface Finishes

Your brand identity and target audience connect with specific colors. You can provide specific Pantone codes to match the desired color. Sunmolin production lines handle both intense solid colors and delicate see-through shades according to your specifications. Surface texture plays an equally important role as color in product design. Select matte, smooth, or embossed textures to provide your customers with a physical texture they can feel. You can make products look like leather and develop unique surface textures to stand out.

Printing and Logo Customization

Having a strong brand image matters most, and Sunmolin lets you add it right onto the webbing product. You can print your design onto the inner webbing material before applying clear PVC protection. The protective layer ensures the design remains visible and intact in challenging environments. Instead of internal printing, you can create your logo or text directly on the outer PVC surface, where it produces strong and clear results. These methods maintain strong performance, which makes them suitable for demanding branding applications.

Special Shapes and Structural Design Variants

The standard webbing shape often fails to match specific needs. Sunmolin helps you create one-of-a-kind designs through custom mould creation. The R&D team develops custom solutions that create precise shapes and structures according to your design requirements. Customized webbing helps products grip better while remaining flexible and appearing visually appealing. Sunmolin uses its toolmaking knowledge to develop custom products that maintain production quality standards.

Stitching vs. Welding Options

Based on your application requirements, you can select between stitching and welding. Stitching proves best for gentle textile materials that need bendability rather than pull resistance. Sunmolin selects thin, flexible webbing materials for its stitching process. Radiofrequency welding shows better results for demanding applications. It produces strong connections between materials while keeping the final result seam-free. Sunmolin assists you in selecting the perfect technique, from stitching or welding, based on your product’s specifications.

Conclusion

You can personalize PVC webbing in both size and shape, plus choose structural elements and color options. Sunmolin delivers design freedom because you can select detailed cutting, bright prints, or personalized shapes based on your needs. After 15 years in business, Sunmolin leverages its advanced equipment and research to transform your creative concepts into reliable products. You’ll receive top-quality complete webbing solutions when you partner with Sunmolin.